Custom Blade Fabrication: The Pinnacle of Precision in Cutting Tools

When it comes to achieving the highest standards in cutting performance, custom blade fabrication emerges as a crucial component in various industries. Whether you’re a chef requiring the perfect knife or a tradesperson in need of specialized tools, the ability to have blades tailored specifically to your requirements can make all the difference. At SZ Blade, we are committed to delivering unparalleled craftsmanship in every blade we produce, ensuring our clients receive tools that meet their exact specifications.

The Importance of Custom Blade Fabrication

The art of custom blade fabrication combines science, engineering, and a deep understanding of materials to create blades that perform optimally in their intended use. Here are several reasons why custom blade fabrication stands out:

- Tailored Solutions: Each industry and individual has unique cutting requirements, making one-size-fits-all solutions inefficient.

- Material Selection: The choice of materials can greatly affect performance. Custom fabrication allows for high-quality materials to be selected based on specific needs.

- Precision Engineering: Custom blades are designed and manufactured using advanced technologies that ensure precision and consistency.

- Performance Enhancement: Properly tailored blades enhance cutting efficiency and reduce user fatigue, leading to better overall performance.

The Process of Custom Blade Fabrication

Custom blade fabrication involves several key stages, each vital to producing a blade that meets the high standards required by professionals. Let's explore these stages:

1. Consultation and Understanding Requirements

The process begins with a thorough consultation. Skilled fabricators work closely with clients to understand their specific needs, including:

- Intended Use: Knowing whether the blade will be used for culinary applications, industrial purposes, or artistic endeavors is essential.

- Desired Specifications: This includes dimensions, thickness, shape, and any design features that are important to the client.

- Maintenance Preferences: Clients often have preferences regarding how easy they want their blades to be to maintain and sharpen.

2. Design and Engineering

After gathering all the information, the next phase involves designing the blade. This is where modern CAD (Computer-Aided Design) software comes into play, allowing for precise modeling. This software can:

- Create 3D models of the blade to visualize its final design.

- Calculate the necessary dimensions and angles for optimal functionality.

- Simulate the blade's performance under various conditions.

3. Material Selection

The choice of materials is critical in blade performance. Common materials include:

- Stainless Steel: Known for its corrosion resistance and durability, ideal for culinary knives.

- Carbon Steel: Offers excellent edge retention and sharpness but requires more maintenance.

- Alloy Steels: Provide a balance between hardness and toughness, suitable for a variety of applications.

4. Fabrication Techniques

With the design and materials chosen, it's time for fabrication, which typically involves several advanced techniques:

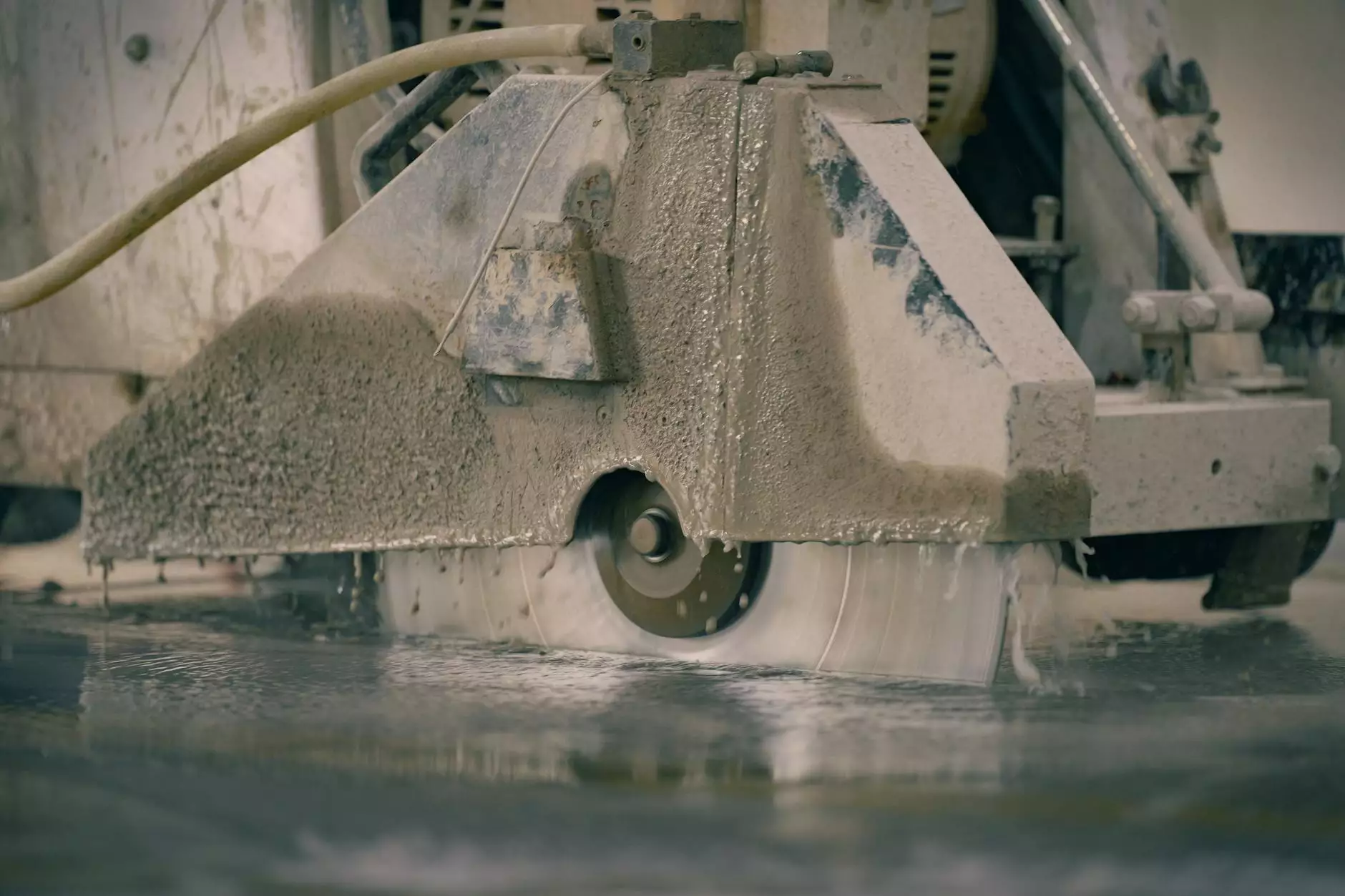

- CNC Machining: Precision cutting and shaping of materials to create the blade’s profile.

- Heat Treatment: Enhancing blade hardness and durability through controlled heating processes.

- Grinding and Honing: Refining the blade’s edge to achieve the desired sharpness.

5. Quality Control

After fabrication, quality control measures are implemented to ensure that each blade meets strict standards. Tests may include:

- Visual inspections for defects.

- Edge sharpness testing for performance evaluation.

- Durability assessments to confirm material integrity.

Applications of Custom Blades

Custom blades have a wide array of applications across many industries:

Culinary Arts

For chefs and culinary experts, nothing beats the precision of a custom knife. Tailoring knives for specific cutting tasks, such as:

- Filleting Fish: Blades designed for the delicacy of fish.

- Chopping Vegetables: Ensured to offer the perfect weight and balance for efficient chopping.

- Precision Slicing: For meats, ensuring minimal resistance during slicing.

Industrial Uses

In various industrial applications, custom blades are essential for tasks such as:

- Cutting Rigid Materials: Custom blades can slice through metal, plastics, and other materials with finesse.

- Packaging: Blades designed for specific packaging machines that require sharpness and durability.

- Woodworking: Specialized blades for precise cuts on different types of wood.

Art and Craft

Artists and hobbyists also benefit from custom blades. Whether it’s for carving, model making, or specialty cutting, custom solutions can:

- Provide the exact blade shape needed for intricate designs.

- Enhance safety and control during the crafting process.

- Allow for personalization in tools based on individual style or technique.

Knife Sharpening as a Complementary Service

At SZ Blade, we not only focus on custom blade fabrication but also on knife sharpening, which is essential for maintaining blade performance. Proper sharpening enhances the life and capability of blades, ensuring optimal performance. Key advantages of professional knife sharpening include:

- Restoring Sharpness: Professional techniques ensure blades regain their original edge.

- Precision: Expert sharpeners know how to achieve the correct angle for different types of blades.

- Maintenance: Regular sharpening prolongs the life of the blade, saving money in the long run.

Choosing the Right Service for Custom Blade Fabrication and Knife Sharpening

Choosing the right service for custom blade fabrication is vital. Here are some tips to ensure you select a reputable provider:

- Experience: Look for companies with a proven track record in custom fabrication and sharpening services.

- Client Testimonials: Feedback from previous clients can provide insight into quality and service.

- Range of Services: Providers that offer a wide range of services are often more knowledgeable and capable of fulfilling specific requests.

- Material Expertise: Knowledge of various materials ensures the best options are available for your specific application.

- Customization Options: A good provider will offer extensive customization to suit individual needs.

Conclusion

Custom blade fabrication is an art that blends skill, precision, and an understanding of materials. At SZ Blade, we are committed to providing our customers with high-quality, tailored cutting solutions that meet the demands of various industries. From the culinary world to industrial applications, having the right tools is essential. Partner with us for your custom blade needs and enjoy the benefits of blades crafted with expertise and attention to detail.

Explore our services and learn how we can transform your cutting tasks with the precision of custom blade fabrication today!