Understanding the Landscape of China CNC Lathe Parts Suppliers

The global manufacturing industry has undergone significant evolution in recent years. With innovative technologies and improved supply chain management, businesses are constantly seeking ways to optimize their production processes. Among the crucial components for precision manufacturing are CNC lathe parts, predominantly sourced from reputable China CNC lathe parts suppliers. This article provides an in-depth exploration of the benefits, the suppliers available, and how businesses can leverage these resources to enhance efficiency and product quality.

What are CNC Lathe Parts?

CNC (Computer Numerical Control) lathe parts are integral to the machining and fabrication processes in various industries. These parts are manufactured using advanced CNC technology, which allows for incredible precision and repeatability. The lathe itself operates by rotating a workpiece against a cutting tool, enabling the creation of complex shapes and fine details.

Key Components of CNC Lathe Machinery

- Spindle: The main rotating part of the CNC lathe that holds the workpiece.

- Tool holders: Attach tools to the spindle for cutting operations.

- Bed: The foundation of the CNC lathe, providing stability and support.

- Control panel: Interface used by operators to control the CNC machine's functionality.

- Chuck: A clamp used to hold the workpiece securely in place.

Benefits of Sourcing from China CNC Lathe Parts Suppliers

China has established itself as a leader in manufacturing, particularly in producing precise CNC lathe parts. Here are some advantages of collaborating with Chinese suppliers:

1. Cost-Effectiveness

Chinese CNC lathe parts suppliers often offer competitive pricing, allowing businesses to acquire high-quality parts at a fraction of the cost compared to local suppliers. The lower labor costs and economies of scale in China contribute to these savings.

2. High-Quality Standards

Many manufacturers in China adhere to strict quality control measures, ensuring that the parts produced meet international standards. Certifications such as ISO can be found among reputable suppliers, providing assurance of the quality of CNC lathe parts.

3. Wide Range of Products

The diversity of CNC parts available from China is vast. Suppliers cater to various industries, from automotive to aerospace, offering custom solutions that meet specific client requirements.

How to Identify Reputable China CNC Lathe Parts Suppliers

When looking for reliable suppliers, it's essential to conduct thorough research and consider several factors to ensure a fruitful partnership:

1. Verify Certifications

Ensure that the supplier has necessary certifications such as ISO 9001, which demonstrates their commitment to quality management systems.

2. Assess Experience and Reputation

Choose suppliers that have a proven track record in the industry, evidenced by customer testimonials and case studies. A well-established supplier will likely have a reputation for providing quality parts consistently.

3. Evaluate Communication and Customer Service

Effective communication is essential when dealing with international vendors. Evaluate how responsive and helpful the supplier is during initial inquiries. Good customer service reflects the supplier’s commitment to your satisfaction.

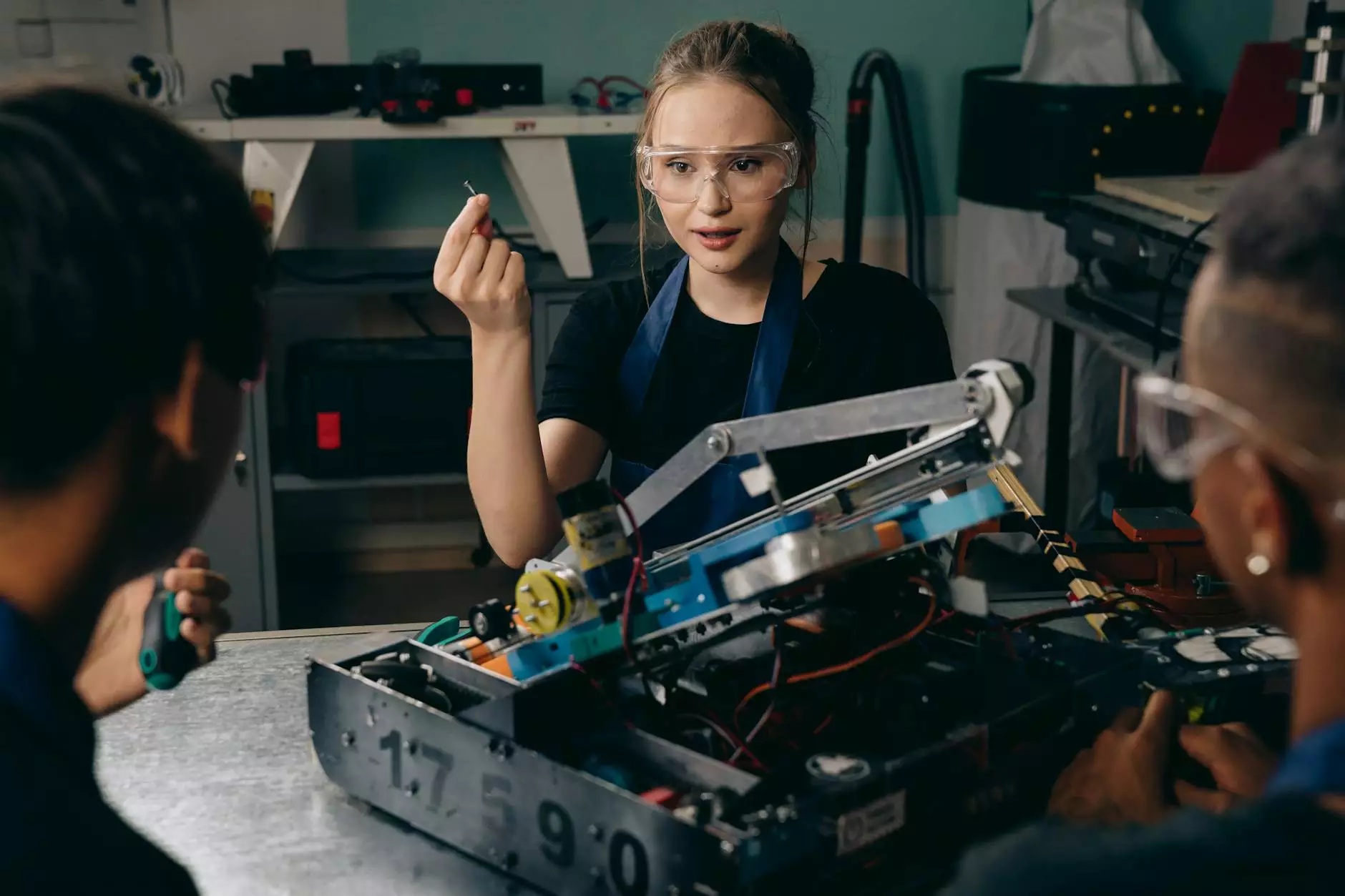

The Role of Metal Fabricators in CNC Lathe Parts Manufacturing

Metal fabricators play an essential role in the production of CNC lathe parts. They specialize in transforming raw materials into finished products through various processes, including cutting, bending, and assembling. Here’s how they contribute:

1. Precision Manufacturing

Using cutting-edge technology, metal fabricators ensure the parts are manufactured with maximum precision. This level of detail is critical in CNC machining, where even the smallest discrepancy can affect operational efficiency.

2. Custom Fabrication Services

Many metal fabricators offer custom services tailored to the unique specifications of clients, allowing for more versatile manufacturing solutions. This capability is especially valuable when working on specialized projects that require unique dimensions or designs.

3. Material Expertise

Fabricators are knowledgeable about various materials, including metals like steel, aluminum, and titanium. Their expertise enables them to recommend the best materials for specific applications, ensuring durability and performance of CNC lathe parts.

Establishing Long-Term Relationships with Suppliers

Building a lasting relationship with China CNC lathe parts suppliers can yield significant advantages for your business, including improved pricing, priority service, and better communication. Here are tips on cultivating these relationships:

1. Communicate Your Needs Clearly

Establishing clear communication regarding your expectations and requirements is crucial. This clarity helps suppliers understand your needs and ensures that both parties are on the same page.

2. Regularly Evaluate Performance

Periodically assess the supplier's performance based on quality, delivery times, and customer service. This evaluation can help identify areas for improvement and potentially strengthen your partnership.

3. Foster Personal Relationships

Whenever possible, visit the supplier's facility to build rapport and gain firsthand insight into their operations. Personal connections can enhance trust and result in a stronger professional relationship.

Case Studies: Success Stories of Businesses Using CNC Lathe Parts from China

Let’s delve into a couple of successful examples of businesses that leveraged the services of China CNC lathe parts suppliers:

Case Study 1: Automotive Parts Manufacturer

A leading automotive parts manufacturer wanted to enhance their production efficiency without compromising quality. By partnering with a reputable Chinese CNC lathe parts supplier, they reduced material costs by 30% while maintaining high product standards. The supplier's commitment to quality control ensured all parts met the required specifications, significantly reducing waste and increasing productivity.

Case Study 2: Aerospace Component Fabrication

An aerospace company needed precision parts manufactured for an upcoming project. They turned to a seasoned Chinese supplier specializing in CNC lathe parts, providing tailored solutions that met stringent aerospace standards. The result was a timely delivery of high-quality parts that enabled the company to launch their product on schedule, enhancing their reputation in the industry.

Conclusion: Maximizing the Benefits of Working with China CNC Lathe Parts Suppliers

In conclusion, the global landscape of China CNC lathe parts suppliers offers numerous opportunities for businesses to enhance their manufacturing processes. By understanding the advantages, identifying reputable suppliers, and cultivating long-term relationships, companies can leverage these resources to achieve cost-effectiveness, quality, and efficiency. As the demand for high-quality precision machining continues to grow, partnering with the right metal fabricators and suppliers will be crucial for maintaining competitive advantage in the industry.

Investing time and resources to find the best supplier can lead to substantial long-term benefits for your business. Whether you're in the automotive, aerospace, or any other manufacturing sector, the right CNC lathe parts can propel your business to new heights of success. Therefore, explore, evaluate, and engage with deepmould.net for reliable solutions to meet your CNC lathe parts needs.