The Precision of Injection Molded Plastics

When it comes to manufacturing, the use of precision injection molded plastics has revolutionized the industry. DeepMould, one of the top Metal Fabricators in the business, specializes in creating high-quality injection molded plastic components that meet the most demanding specifications and standards.

Benefits of Precision Injection Molded Plastics

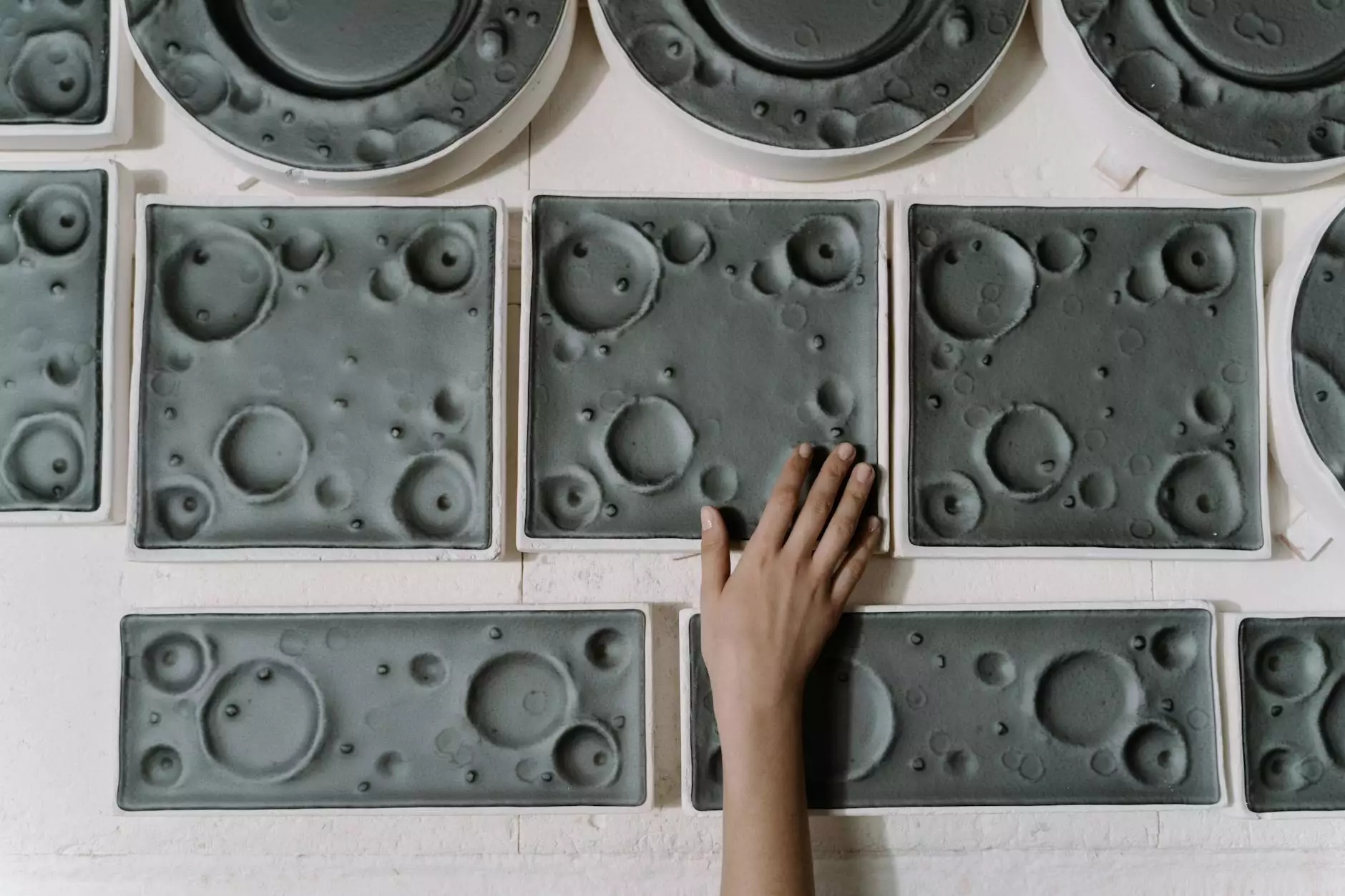

Injection molding is a process where molten material is injected into a mold cavity, allowing for high production volumes with consistent quality and precision. Here are some key benefits of using precision injection molded plastics:

- Precision: The accuracy and detail achieved through injection molding are unparalleled. DeepMould's state-of-the-art machinery ensures that every plastic component is produced with utmost precision.

- Efficiency: Injection molding allows for quick production cycles, reducing lead times and increasing overall efficiency in manufacturing processes.

- Quality: The materials used in injection molding are carefully selected for their durability and versatility, resulting in high-quality finished products.

- Customization: With injection molding, it is easy to customize components to meet specific design requirements, giving businesses the flexibility they need.

DeepMould: Your Trusted Partner in Injection Molding

As a leading provider of precision injection molded plastics, DeepMould stands out for their commitment to excellence and innovation. Their team of skilled engineers and technicians work tirelessly to ensure that every product meets the highest standards of quality and precision.

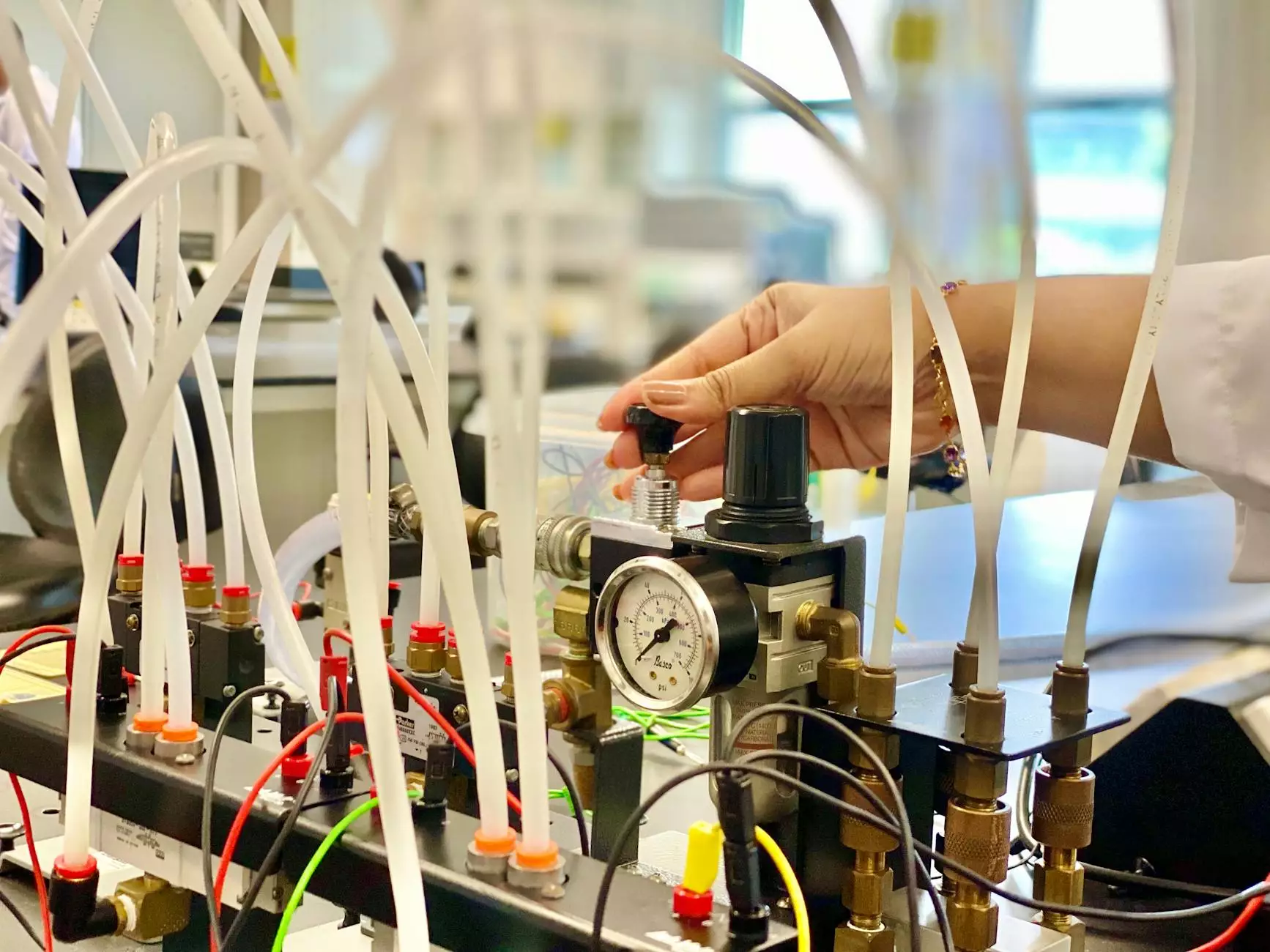

Advanced Technology

DeepMould invests in state-of-the-art injection molding technology to deliver superior results. Their cutting-edge machinery and equipment enable them to produce complex parts with tight tolerances, catering to a wide range of industries.

Quality Assurance

Quality is paramount at DeepMould. Stringent quality control measures are in place throughout the production process to guarantee that every component meets the exact specifications outlined by the client. This commitment to quality sets DeepMould apart from the competition.

Applications of Precision Injection Molded Plastics

The versatility of precision injection molded plastics makes them ideal for a variety of applications across different industries:

- Automotive: From interior components to under-the-hood parts, injection molded plastics play a crucial role in the automotive industry.

- Electronics: Precision plastic components are commonly used in electronic devices, ensuring both functionality and durability.

- Medical: Injection molded plastics are vital in the medical field, where sterility and precision are paramount.

- Consumer Goods: Many consumer products rely on precision injection molded plastics for their design and functionality.

Conclusion

For businesses looking for top-notch precision injection molded plastics, DeepMould is the go-to choice. With a focus on quality, precision, and innovation, DeepMould sets the standard for excellence in the industry. Partner with DeepMould today and experience the difference that precision injection molding can make for your business.